My final Project doesn't have a mechanism so I didn't have any specific task to make for this assignment. However, I've always been interested in mechanisms that work with tension and I wanted to try an idea I've had for a while that I can implement in other projects. I designed a system that goes up and down by streching a rubber band, using a laser-cut gear mechanism, bearings, wire and a servo.

Download the files here:

2D drawings for Laser Cutting [.dwg]

3D model in Rhinoceros [.3dm]

FabAcademy2014: Mechanisms & Machines from Alejandra Diaz de Leon on Vimeo.

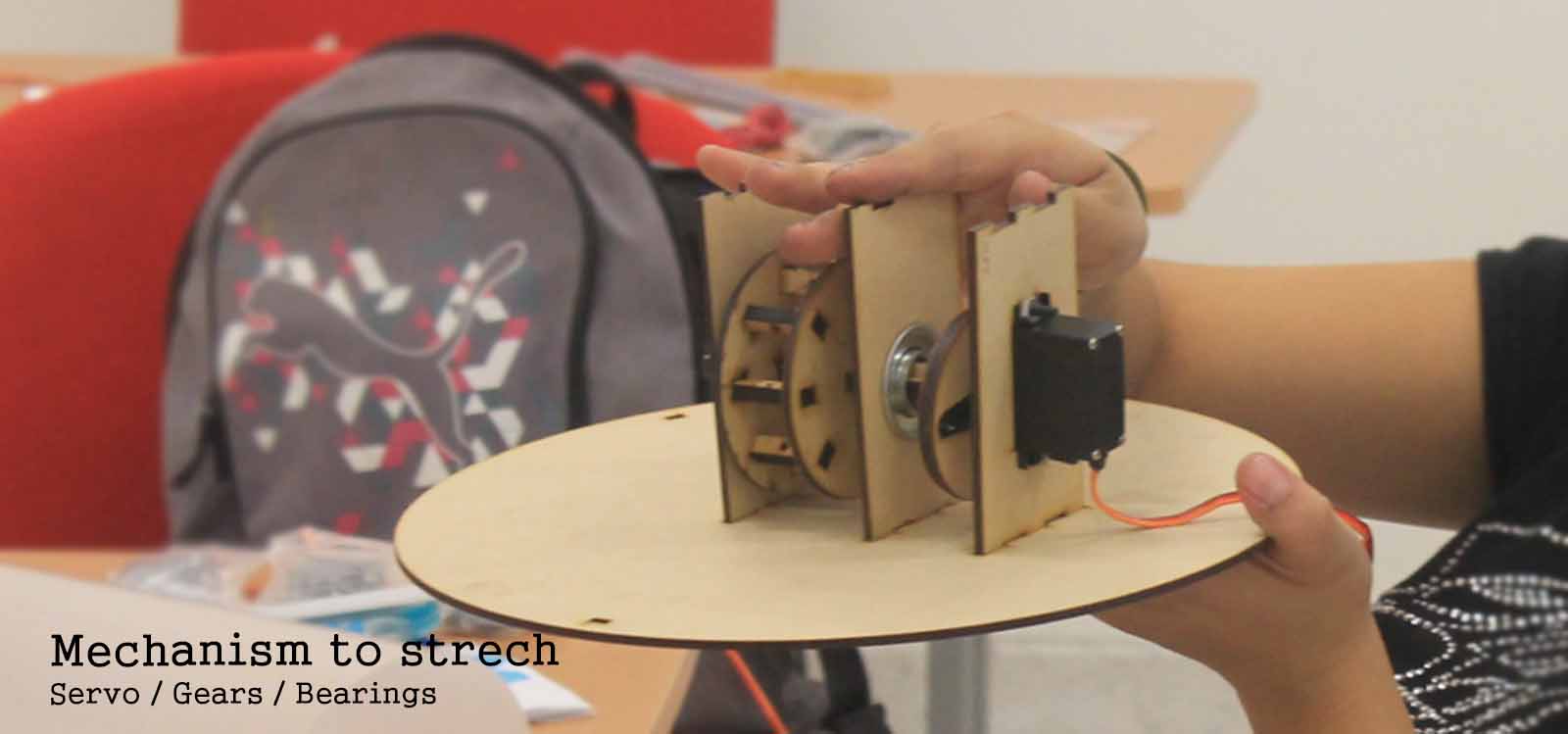

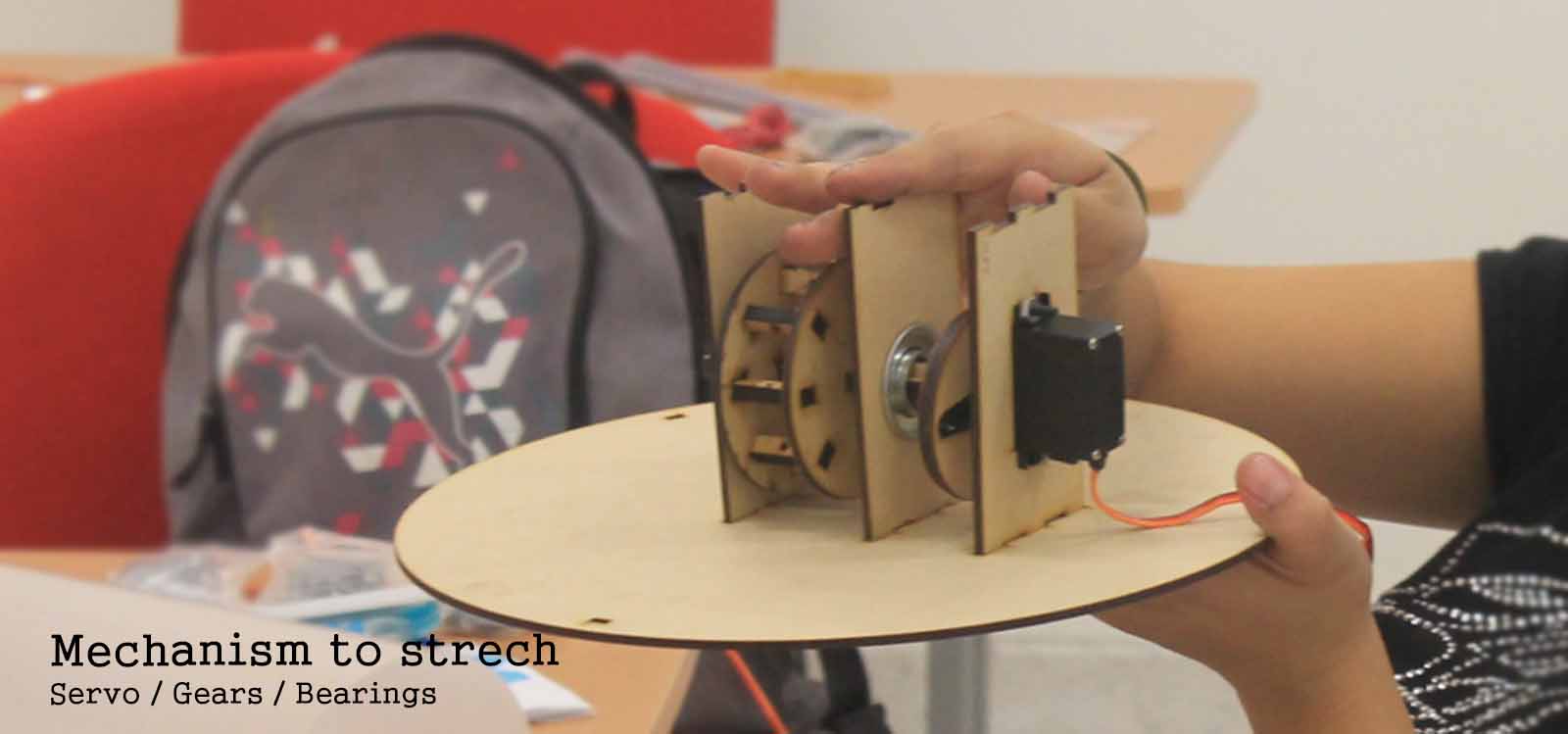

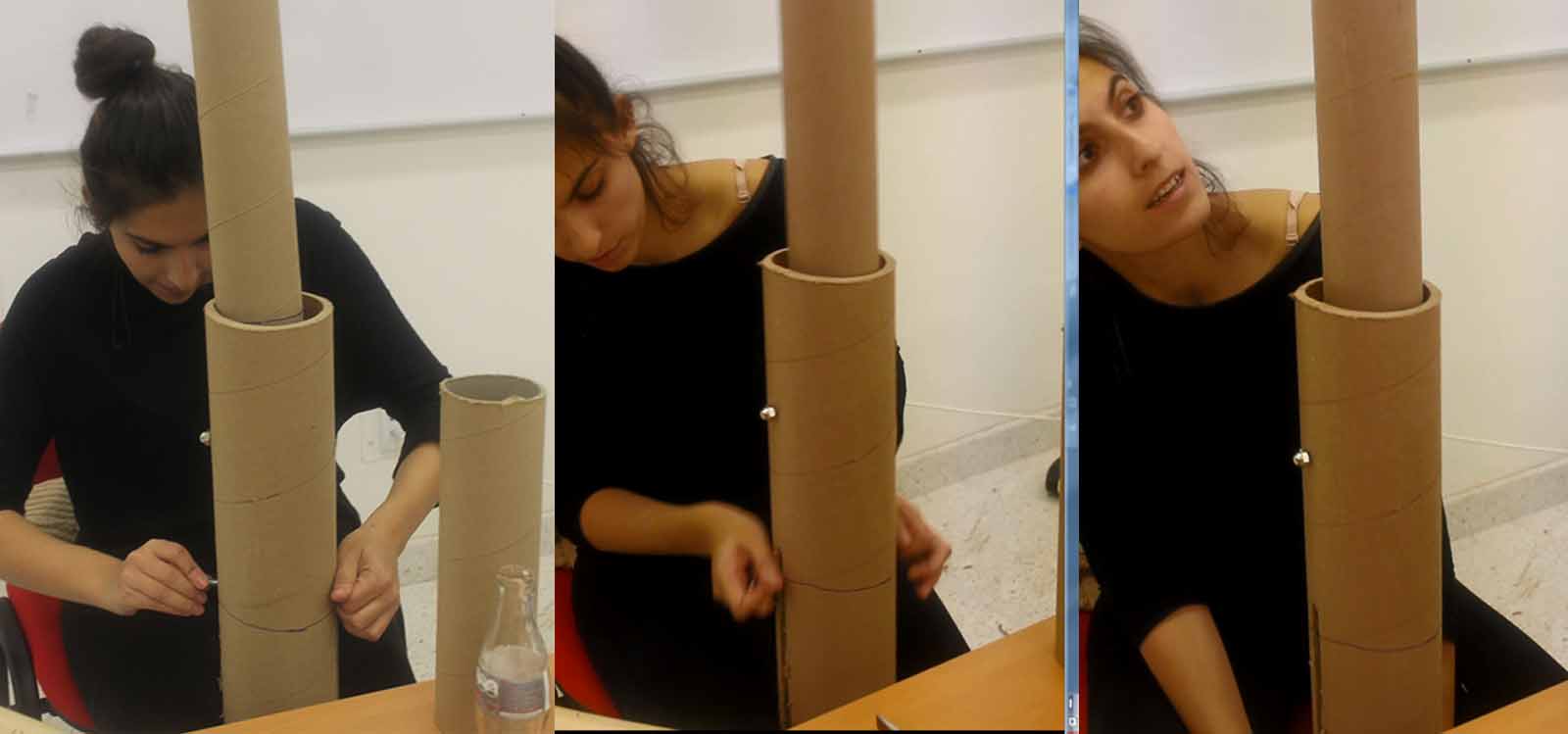

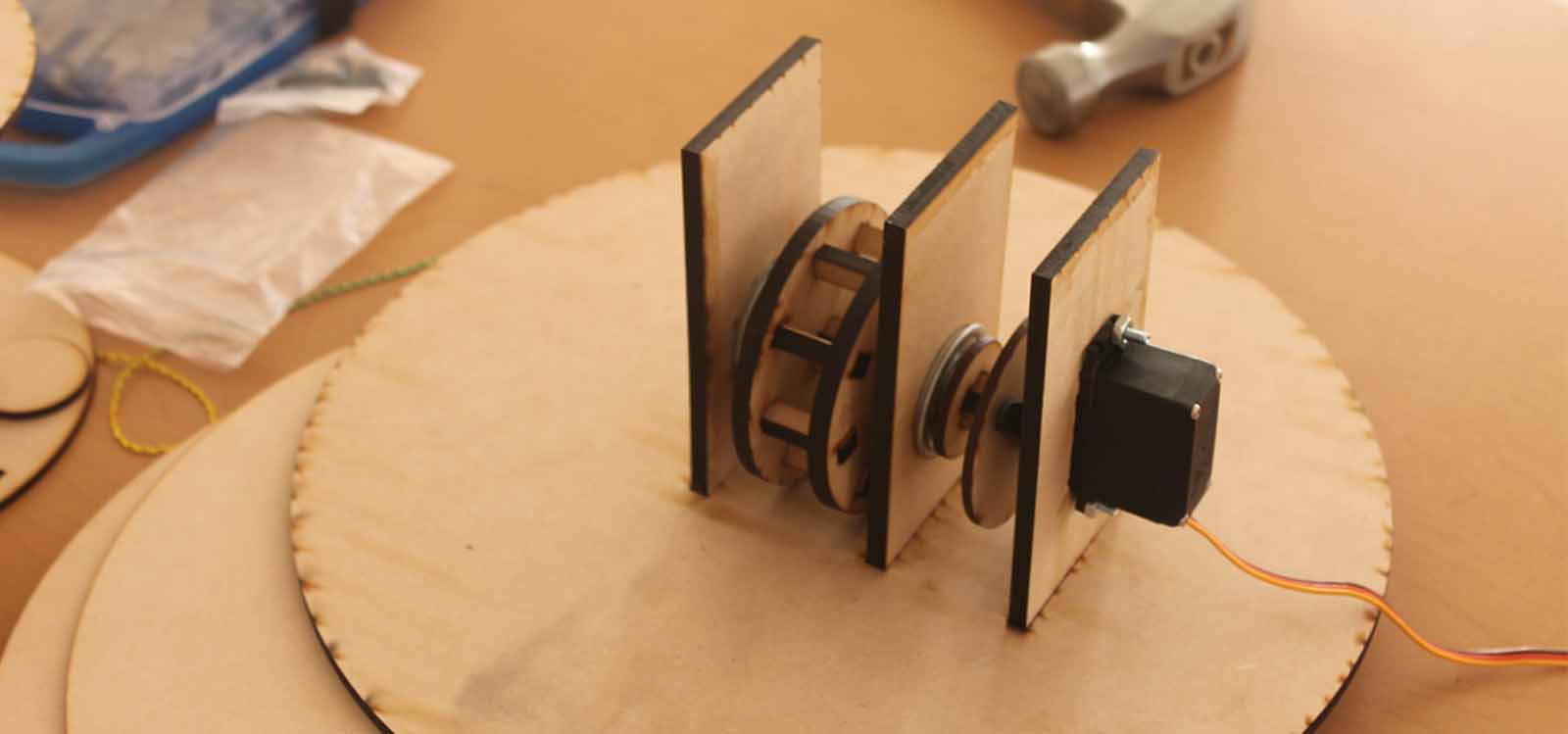

For this assignment I wanted to try a mechanism that works with tension so I designed a system to strech a rubber band by pulling it down with a gear and a servo. The idea is to fabricate a mechanism than can be attached to anything to move up and down.

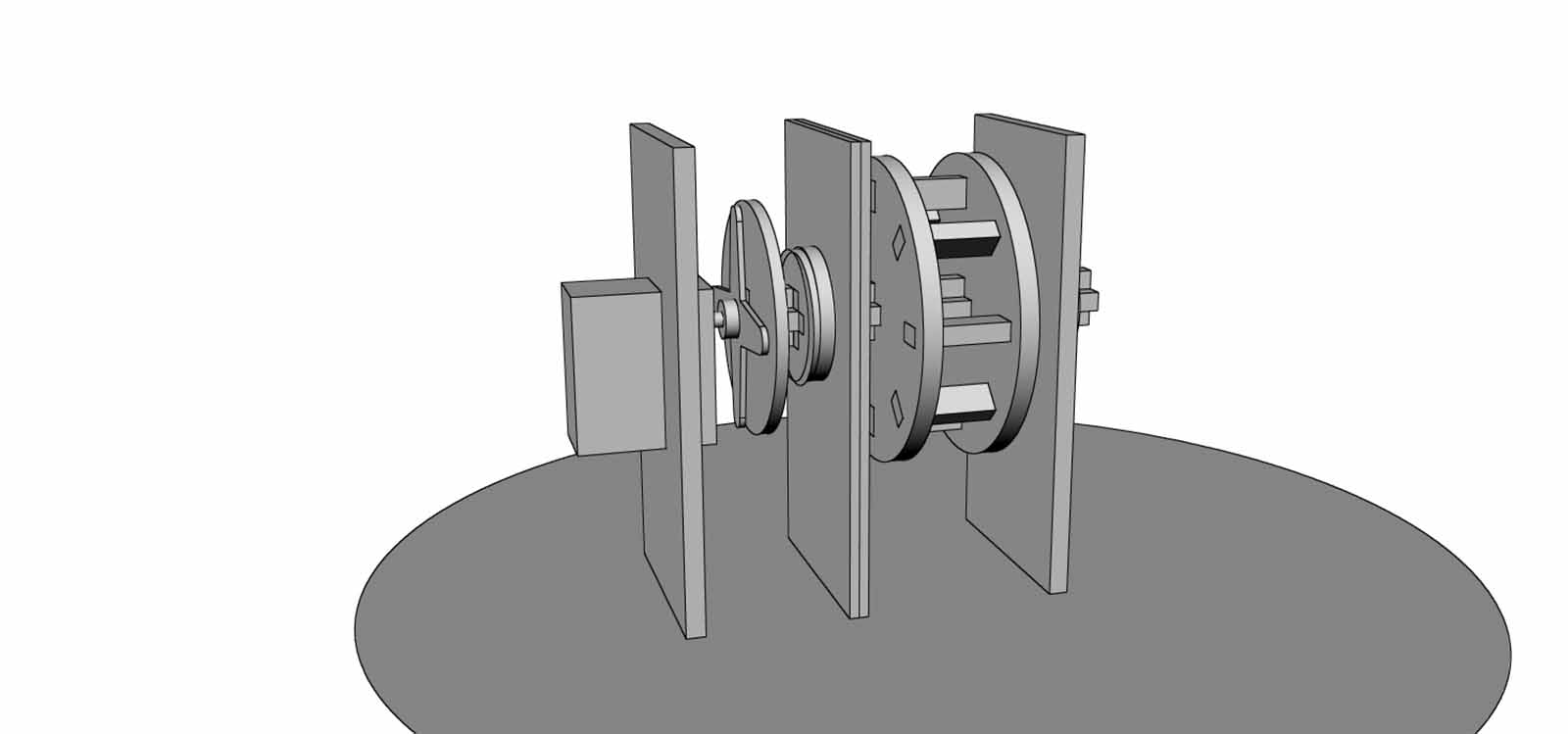

First, I defined the mechanism and made a 3D model of it in Rhino to make sure all the elements fit together. I also had to 3D model the servo and bearings with precise messaurements to avoid they didn't fit well. The aim is to test this prototype in 3mm MDF for laser cutting. I took the curves of the edges and borders of the geometry of each element of the 3D model and made the 2D drawing for laser cutting the pieces. I made the first test and the bearings and servo didn't fit. They were too big, so I changed the drawings and gave to all the perforations of the mechanism a +0.5mm tolerance.

Later on, I assembled all the parts and realized that I had to design a small platform for making the mechanism stable. Once I also cut it, I could assemble it without a problem as it is shown in the picture below.

Afterwards, I tested the mechanism. I used the Arduino IDE to download a simple "Sweep" example into the Arduino connected to the servo. Since it's a hacked servo (I remove the stops to make it rotate 360 degrees), I only kept the part of the code that rotates to 180 degrees. It workes!.

Finally, I found some weakness that I would need to fix if I wanted to implement it in a project:

a. The mechanism rolls smoothly, however, the space in between the gears is too big and doesn't have anything to hold the wire or cable that goes in the middle. It would move around and would probably tangle up around the gear.

b. The way the servo is attached to the mechanism is too weak and wouldn't be strong enough.

c. The base of the mechanism has to be stronger too, otherwise it moves around a little and looses stability.

To watch the video of the mechanism working properly, go to the top ot this webpage!